World Class Manufacturing is the philosophy of being the best, the fastest, and the least cost producer, offering more value for a product or service through continuous improvement of manufacturing systems by making processes less wasteful and more reliable.

Beginning with one manufacturing plant, TAFE has around 10 manufacturing units in India. It is the third largest manufacturer of tractors in the world, meeting the needs of farmers in over 80 countries. The remarkable foresight to develop both the business and farming community steers the organization in the right direction. It proactively takes measures through policy and processes, from sourcing raw materials to the destination and beyond.

TAFE has set up a process-driven approach to world-class manufacturing.

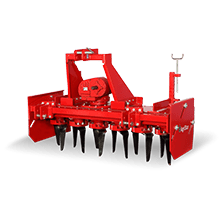

FLEXIBILITY

The Flexible Manufacturing System (FMS) of production is designed to adapt to fast changes. The plants are configured to produce a variety of tractor models and seamlessly tackle changing levels of production. FMS drives efficiency and enhances effectiveness, which leads to reduced downtime since the production line is effortlessly integrated.

TAFE’s production process is compatible with manufacturing at various operating plants/ systems with the help of automation, streamlining, and modern technologies. The Mixed model production method where distinct products and models are produced and assembled in the same assembly line leads to optimum utilization of men and materials.

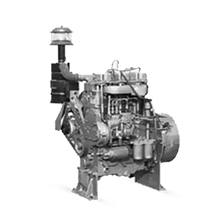

ZERO DEFECT

Zero defects manufacturing is a continuous process that has always been the ultimate target for any manufacturing industry to achieve. With the rise of Industry 4.0 and the implementation of new technologies, it is now possible to emphasize control of all functions of the process, which allows for predicting defects at any stage of manufacturing. The stored data makes analyses possible to determine solutions for existing and probable future causes.

TAFE’s Zero-Defect tractor program has set a benchmark by increasing product quality through the upgradation of transcending technologies.

GREEN ADOPTION

Sustainability is at the heart of TAFE’s manufacturing process. Even before formal guidelines were in place, TAFE has been continuously adopting green measures to reduce its carbon footprint. The organization does not consider its role complete with the simple handing over of the product. Every initiative is planned and executed keeping in mind its role in uplifting our communities for a sustainable tomorrow.

Ambient air quality is regularly measured and kept within limits, ensuring the quality of life, of our people and the communities. Greenhouse gas (GHC) calculation templates are provided to all the manufacturing units.

TAFE strives to reduce fuel consumption per tractor through continuous innovation and improvements in processes aimed at achieving energy–efficient operations. All the plants are actively seeking ways to reduce power consumption across the organization. Efforts to reduce solid waste and hazardous waste generation to ensure compliance with company-suggested norms with a comprehensive action plan have been undertaken by the organization. TAFE has also invested in pilot projects that explore the viability of Solar energy as an efficient power source.

Every parameter of environmental sustainability is linked to an ambitious target, stricter than government-proposed norms. This stands testimony to the solemnity that TAFE attaches to sustainability. Common Assessment parameters for all plants are compared with the benchmark criteria, identifying gaps for taking initiatives and cross deployment of best practices for holistic growth of the organization.

LEAN

The lean basics of continuous improvement, delivering value to the customers, and eliminating waste as defined by the Toyota Production System (TPS) is the keystone to success in today’s competitive market. TAFE’s products are centered around the lean basics of what the customers want, the same achieved through mapping the value stream i.e., the complete life cycle of the product, flow of products, and creating a pull for products. Incremental changes at the workplace for efficient results, help TAFE to seek perfection in products and conquer the basic principles of the lean system, which is based on continuous improvement.

SAFETY

In order to align practices across locations, special teams focused on the deployment of common dashboards & metrics are reviewed via Management Information System (MIS). The measures are deployed after comparing them with external benchmarking. One TAFE pursuit with planned common activities across locations during Safety Week celebrations is also undertaken to align with common practices.

Adhering to legal and other requirements as applicable to the safety and quality of products, energy uses, environmental aspects, and Occupational Health & Safety hazards are the guiding principles upon which customized guidelines suitable for the organization are built and deployed. A Common Safety Manual has been developed to control and monitor all practices on safety across the organization. Safe & Environment-friendly systems and work practices have been introduced to energy-efficient and effective operations which stands as the bedrock of TAFE’s safety policy.

TPM & TQM

TAFE has attained the WCM status by taking quality and comprehensive maintenance activity with its state of art streamlined manufacturing capacity and reduction in lead time.

TAFE has garnered the ‘TPM Excellence Award’ from the Japan Institute of Plant Maintenance (JIPM), for its commitment to Total Quality Movement (TQM). Our products and services serve as the industry benchmark of quality with an array of global management systems- 5S, Kanban, Kaizen, and Six Sigma, to name a few. TAFE has over fifty quality circles in place and the tractor plants are certified under ISO 9001 (Quality Management System), ISO 45001 (OHSMS), and ISO 14001 (Environmental Management System) for their environment-friendly operations. Our commitment to the safety of employees is ensured through external safety education and job-specific classroom training.

CONNECTED

Industry 4.0 is mostly focused on using data as a resource through Artificial Intelligence and machine learning. The automated industrial process not only makes quality products but also, leverages the benefits of digital technology. TAFE is renowned for its innovative design and engineering expertise. Through IT-enabled processes, our researchers have considerably reduced launch cycle times for new products, to meet the market demand. Our products hit the market Just in Time of necessity.

TAFE lays emphasis on the continuous development of people, processes, and organizations. The true test of good corporate lies in synchronizing these three elements by aligning the company’s values with the employees’ value system. This is a crucial step to improving productivity through mutual trust and growth.